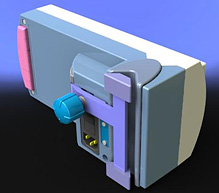

SurX needed a dedicated R.F. Generator to supply the Disposable SurLap handle. Major concerns were the unit’s interface and ease of use,  along with appearance and manufacturing. It had to hold up well over a long expected clinical life. Assembly was also important, as it was going to be done in-house.

along with appearance and manufacturing. It had to hold up well over a long expected clinical life. Assembly was also important, as it was going to be done in-house.

Strategy

We first addressed the interface questions, to make full use of the “soft keys” and layered menu display. The design of the pole clamp was

also very important, to allow easy set-up and storage. Process and vendor research was done at each step of the design to make sure every part was done in the best, most cost effective way possible, while fitting with the disposable handle’s appearance.

Solution

Extensive use was made of molded elastomer, to carry the material from the handle’s trigger and cable boot. The elastomer was functionally appropriate wherever it was used: the R.F. connector boot, the soft keys, the pole mounting clamp, LCD gasket, and the hand grip detail. The housing was carefully designed in ABS to make full use of the advantages of injection molding for assembly, part alignment, and appearance detail.