Boston Scientific’s new Embolic Coils were designed to be more conforming in a wider range of aneurysm sizes and shapes than their competitor’s coils, but demonstrating this on a sales call was difficult, involving a bulky and wet "flow model", as well as many cast aneurisms to show different shapes. And to show the process in a viewable size required an expensive camera or a fluoroscope.

Strategy

The client wanted something that was easy to carry and use, and really showed the advantages of the product. The required quantities were low and “on the fly” revisions were anticipated, so production processes had to be appropriate.

Solution

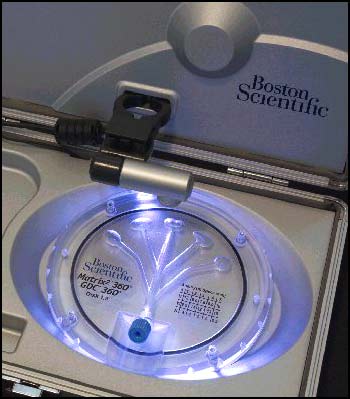

The Kardel Group, in collaboration with a trusted machining vendor, developed a way of manufacturing sealed plexiglas disks with an array of aneurysms inside that could be imaged by a modified “web cam” and displayed on the salesperson’s notebook computer. Cast urethane panels inside an off-the-shelf case gave easy transport and storage at an acceptable price.